FP7 - ENOVAL

Funding source:

|

FP7 |

Start: |

2013 |

End: |

2016 |

Context

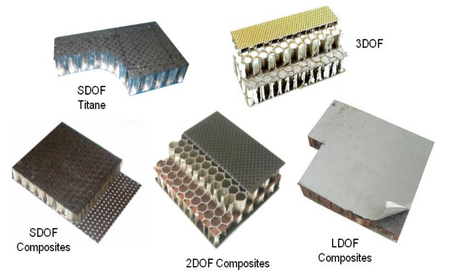

ENOVAL is a EU-funded project aiming at developping novel aircraft engines architectures (geared and ungeared) achieving breakthrough performances in terms of environmental pollution (carbon dioxyde emission efficiency, noise reduction). A direction towards CO2 reduction lies in shortening the engine nacelle, thus leaving less space for acoustic lining (conventional sound absorbers). In that frame, the development of surface acoustic absorbers concepts with subwavelength dimensions is targeted.

In this project, EPFL is a subcontractor of the French nacelle manufacturer AIRCELLE, and collaborates with FEMTO-ST (Besançon, France) to develop novel acoustic liners concepts with distributed active acoustic impedance control features. The technology is based on the Electroacoustic Absorber concept developped at EPFL, combined with distributed acoustic impedance control strategies developped at FEMTO-ST.

Motivation

|

Acoustic liners are a widespread solution for noise mitigation at aircraft engine level, thanks to lightweight However, their passive principle prevents the adaptation to varying engine speeds and therefore lowers their |

|

Conventional liners:

| Limitations | Solutions |

|

|

|

|

|

|

All these specifications lead to adapting Electroacoustic Absorbers to a novel acoustic liner concept.

Concept Development

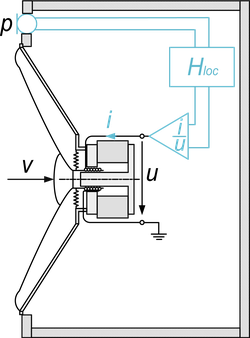

The Electroacoustic Absorber concept: loudspeaker acoustic impedance imposed through a “specific feedforward control”:

Electroacoustic absorber concept:

The control law assigns a prescribed electrical current I to the loudspeaker as a function of the sensed sound pressure P. It allows adjusting the membrane velocity to the incident sound pressure, thus modifying the acoustic impedance presented by the loudspeaker diahpragm, considered here as a membrane resonator. The absorption performance of the membrane is then modified according to this prescribed acoustic impedance. |

|

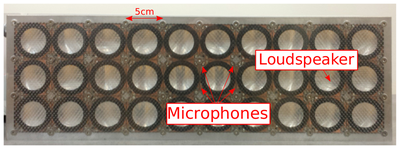

The active acoustic liner concept:

The active acoustic liner is composed of a 2D arrangement of individual electroacoustic absorbers, each being individually controlled so as to present a prescribed acoustic impedance, thus sound absorption properties.

Prototype development

| Unit-cell | Front view | Back view |

|

|

|

Experimental validation

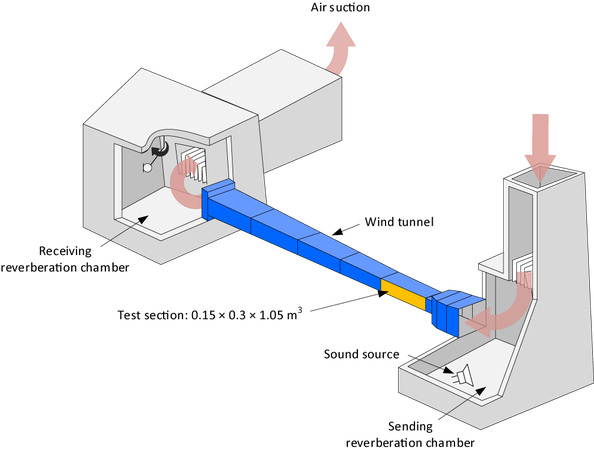

Assessment in the Acoustic Flow Duct facility at NLR (Amsterdam). Measurement of Insertion Losses with the acoustic treatment, in the presence of weak flow (Mach 0.15)

|

|

| NLR's Acoustic Flow Duct facility | Measured Insertion Losses (IL) with the active acoustic liner prototype |

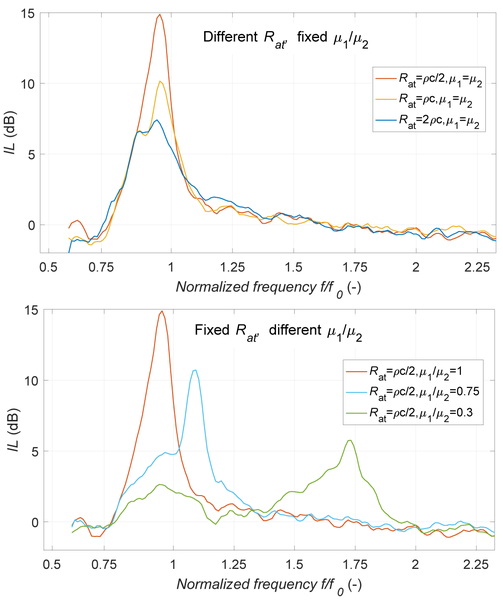

The measured Insertion Losses (IL) exceed 15 dB around the natural resonance frequency of the electroacoustic absorbers, and can be tuned to target a varying frequency over 2 octaves.

References:

- Lissek, H., Boulandet, R., and Fleury, R., Electroacoustic Absorbers: bridging the gap between shunt loudspeakers and active sound absorption, The Journal of the Acoustical Society of America, 129(5), p. 2968, 2011.

- Collet, M., David, P. and Berthillier, M., Active acoustical impedance using distributed electrodynamical transducers, The Journal of the Acoustical Society of America, 125(2), p. 882, 2009.

- E. Rivet, S. Karkar, and H. Lissek, “Broadband low-frequency electroacoustic absorbers through hybrid sensor- / shunt-based impedance control”, IEEE Transactions on Control Systems Technology 25 (1), pp. 63-72 (2017).

- S. Karkar, H. Lissek, M. Collet, M. Ouisse, and M. Versaevel, “Control strategies for a distributed active acoustic skin”, Proc. of Internoise 2015, San Francisco, USA (2015).